This feature is designed to formulate a blend to inventory (for stockpile) instead of invoicing the resulting blended material. It combines the power of the Blending module and the manufactured blend function. There are several uses for Blend to Stock functionality including bulk liquid fertilizer, bagged feed, and bagged fertilizer.

From Weights

- Create an unloaded Blend Ticket to use for mixing material.

- Navigate to Blending / Edit / Blend to Stock / From Weights and highlight the desired ticket. Select OK.

- On the Edit Blend to Stock window, enter the overall net weight in the Gross column or the Gross and Tare weights in the appropriate columns. Choose Apply to prorate it over the analysis Products. Choose OK.

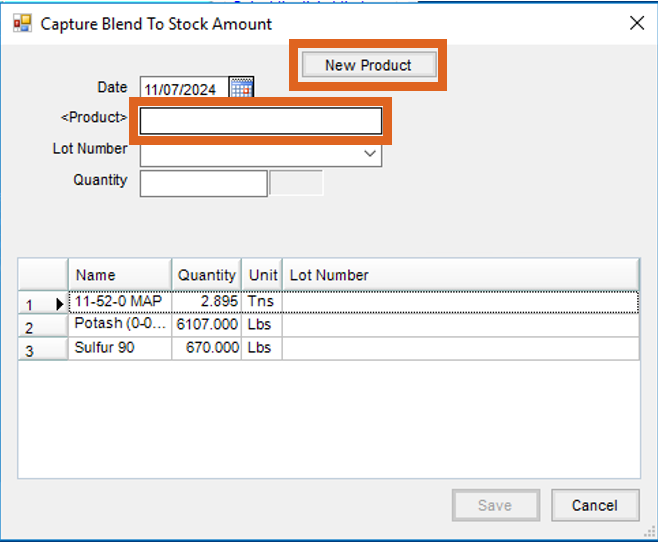

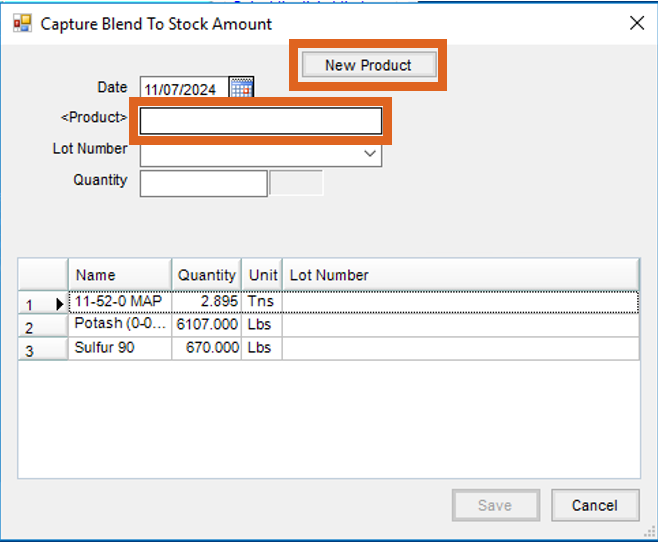

- On the Capture Blend to Stock Amount window, double-click in the Product column to select an existing Product. Select New Product to add a new Product, enter the information, and select Save.

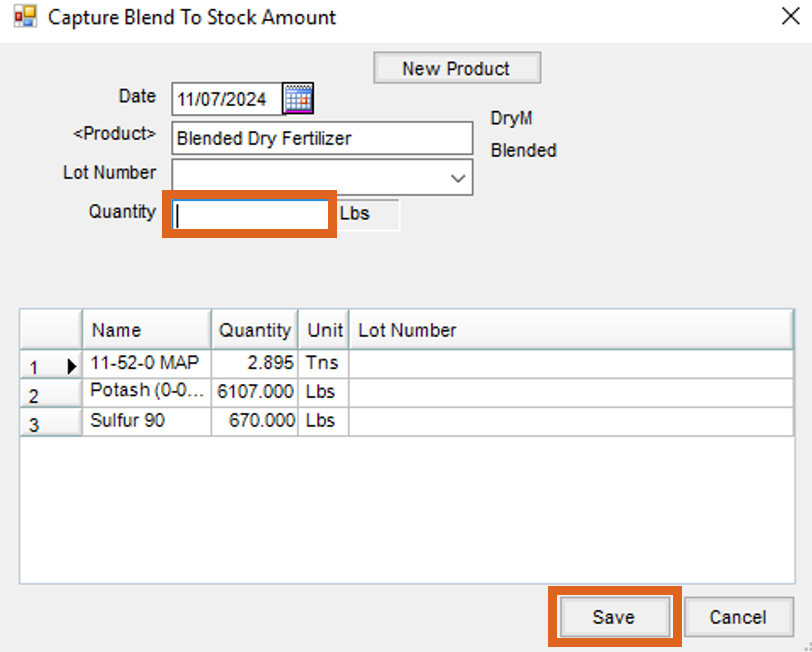

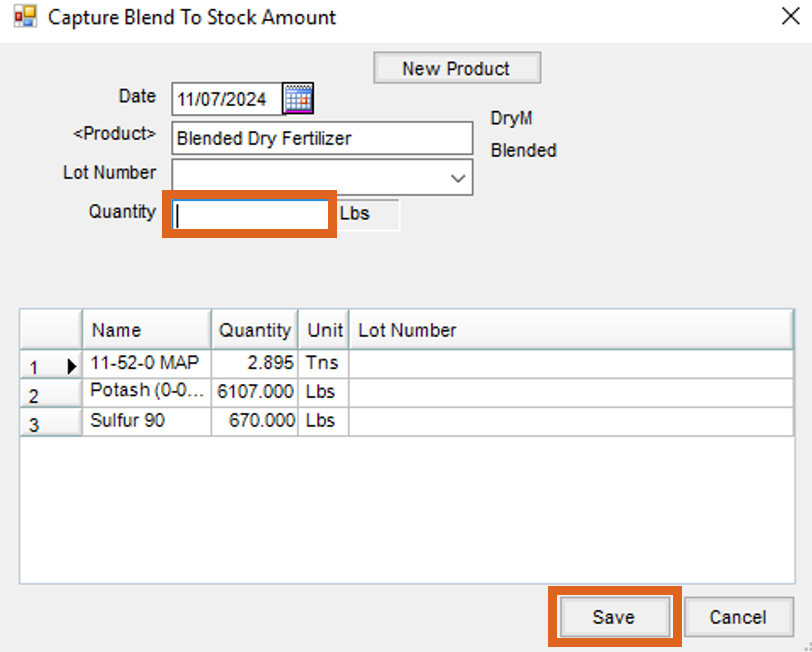

- After the Product is selected, indicate the Quantity of the final Product produced, and select Save.

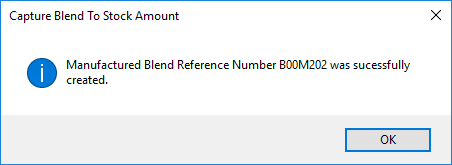

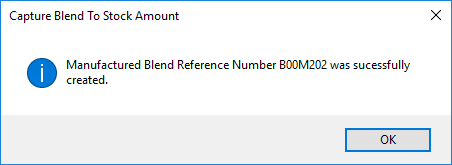

- A message indicates the Manufactured Inventory was created successfully and provides a reference number. Choose OK.

- The Blend Ticket is marked as Processed and the Amount on Hand of the selected Product is increased by the Quantity.

From Automated Blender File

Only files that have been sent to the Automated Blender, processed, and sent back to Agvance are available to import.

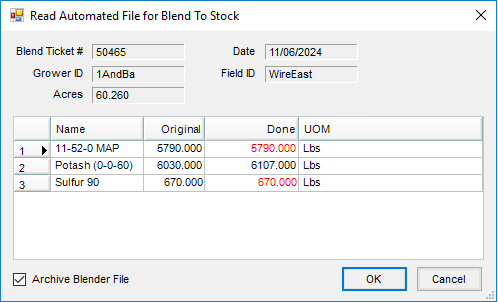

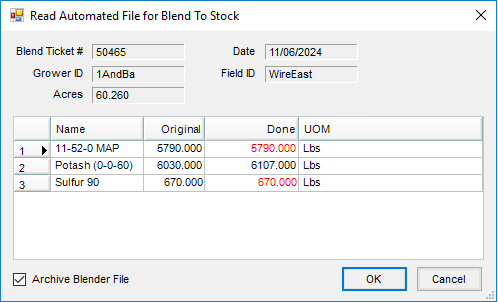

- Navigate to Blending / Edit / Blend to Stock / From Automated Blender File. Highlight the Automated Blender File Ticket to import and select OK.

- On the Read Automated File for Blend To Stock window, verify the displayed values. The Done weights can be edited at this window. Select OK.

- On the Capture Blend To Stock Amount window, double-click in the Product column to select an existing Product. Select New Product to add a new Product, enter the information, and select Save.

- After the Product is selected, enter the Quantity of the final Product produced. Choose Save.

- A message indicates the Manufactured Inventory was successfully created and a reference number is provided. Choose OK.

Posting Notes

- Inventory Detail – An inventory record is made for the finished product and each raw material for an audit trail of inventory activity.

- Inventory Amount on Hand – The product’s Amount on Hand quantity is updated for each of the products involved. The quantity is increased for the finished product and decreased for each raw material.

- Finished Product Cost – The blended product's Average and Last Cost is updated based on the cost of the raw materials.

- General Ledger:

| General Journal Entry | Debits | Credits |

|---|---|---|

| Total cost of all raw materials | Cost of Sales for finished product | |

| Each raw material cost | Cost of Sales for each raw material product | |

| If using Transactional Inventory valuation | ||

| Total cost of all raw materials | Inventory Asset for finished product | |

| Each raw material cost | Inventory Asset for each raw material product |