The process for setting a specific gravity value on dry Products routinely added into liquid blends in order to receive an accurate Blend Density calculation and Estimated Salt Out Temperature.

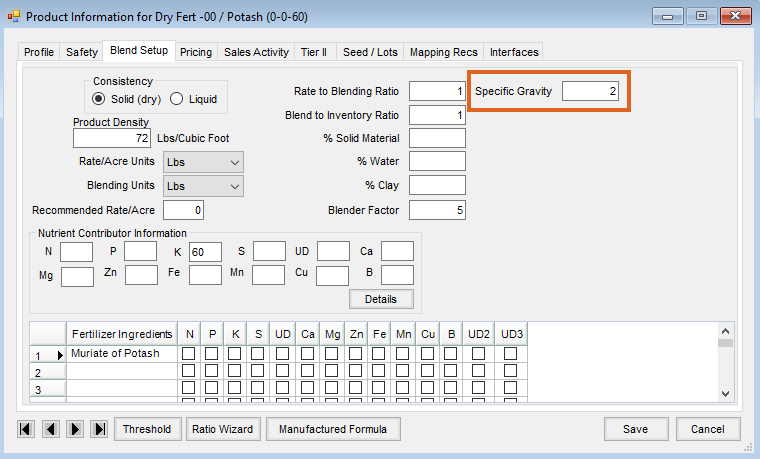

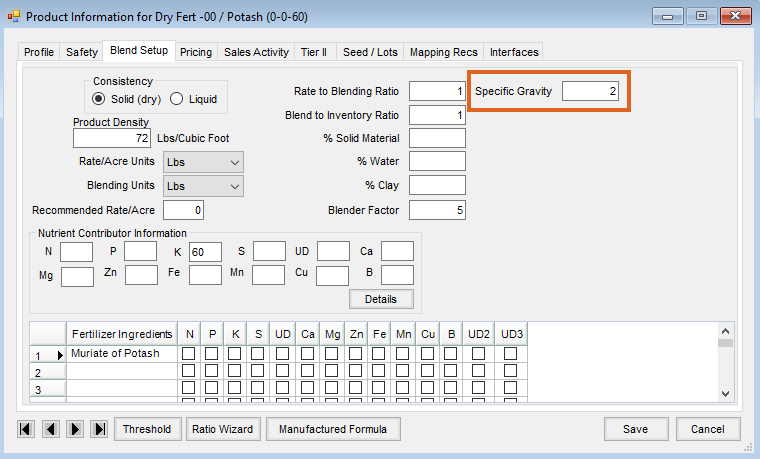

Part 1: Agvance Accounting Setup

- Edit the Product at Accounting / File / Open / Products and go to the Blend Setup tab.

- Enter 2 in the Specific Gravity field.

Note: Agvance Blending uses the Specific Gravity value when the dry Product goes into a liquid blend. If no Specific Gravity is entered, Blending will use the value entered in Product Density which will result in calculated blend densities that are not as accurate.

- Choose Save.

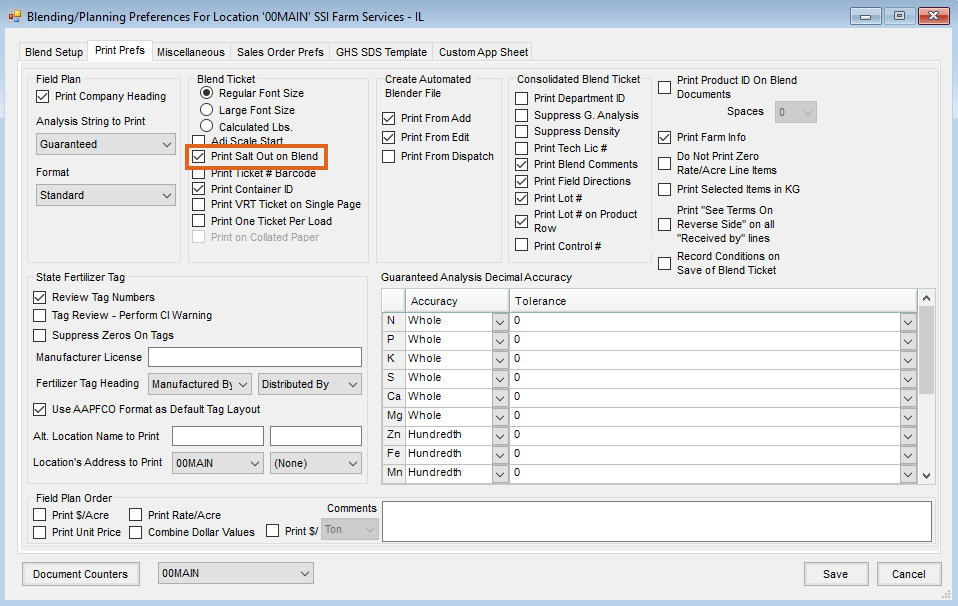

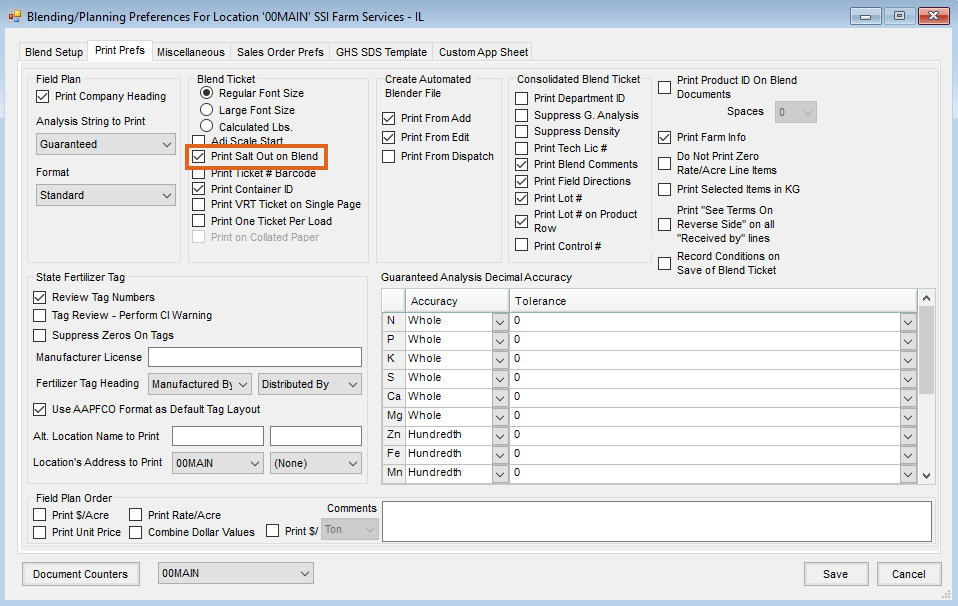

Part 2: Agvance Blending Setup

- Go to Blending / Setup / Location Preferences / Print Prefs.

- Check Print Salt Out on Blend.

- Choose Save.

Note: When formulating blends, Agvance will now result in an accurate calculated Density and Estimated Salt Out Temperature. The following example is for a Blend Ticket for an Agvance formulated 9-18-9 analysis mix for 78.8 acres.

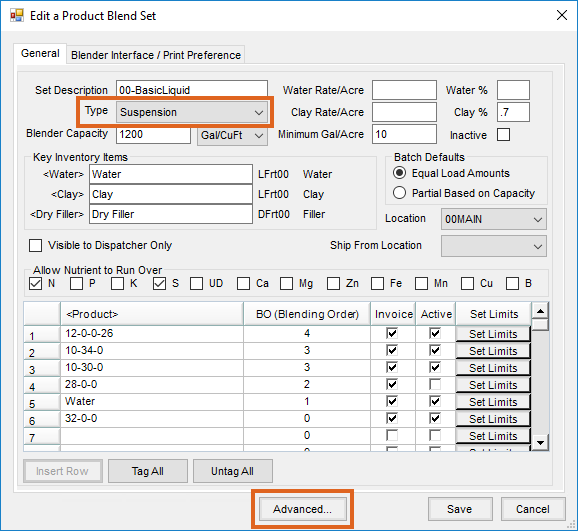

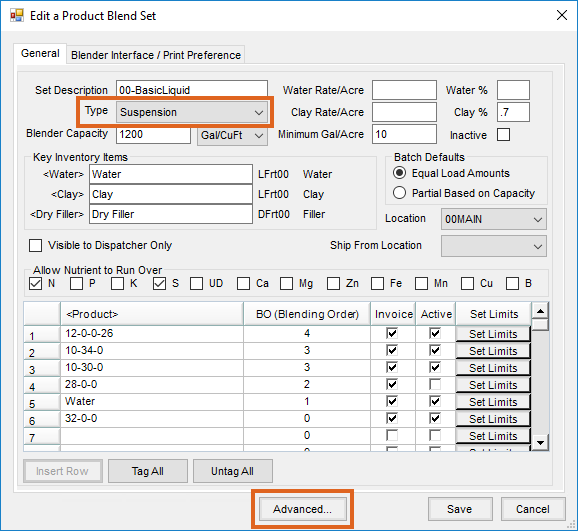

Part 3: Enable a Salt Out Temperature to be Included and Printed on a Blend Ticket

- Go to Blending / Setup / Product Sets and edit a Liquid Type Product Set.

- Choose Suspension as the Type.

Note: This allows a maximum salt out temperature to be set. - Choose Advanced.

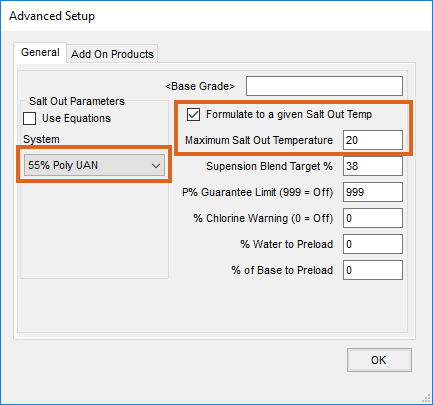

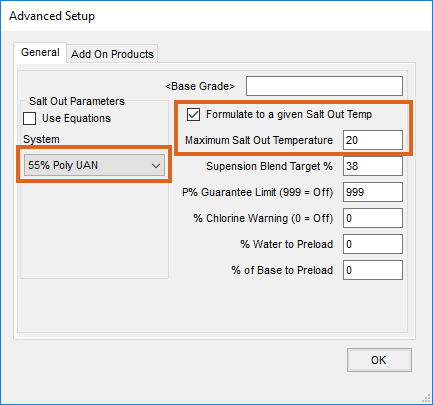

- Choose 55% Poly UAN under the System drop-down.

- Check Formulate to a given Salt Out Temp.

Note: Checking this box allows the program to verify the salt out temperature during formulation and adjust if needed. This checkbox is only available for the Suspension Product Sets when Use Equations is not checked. One of the Salt Out Parameter Systems must be set to formulate to a salt out temperature. If formulating to a given salt out temp, then set the Suspension Blend Target % to 999.

Note: Checking this box allows the program to verify the salt out temperature during formulation and adjust if needed. This checkbox is only available for the Suspension Product Sets when Use Equations is not checked. One of the Salt Out Parameter Systems must be set to formulate to a salt out temperature. If formulating to a given salt out temp, then set the Suspension Blend Target % to 999. - Enter 20 as the Maximum Salt Out Temperature.

Note: This is the maximum temperature to be used for a Suspension Product Set. Use Equations must not be checked for this option to be enabled. The Max Salt Out Temperature value can be adjusted to the time of the season. - Choose OK.

Additional Information – Explanation of Advanced Setup Window Options

Salt Out Parameters System Options

- No Poly UAN – For solutions that contain Urea Ammonium Nitrate (UAN) solution and no ammonium polyphosphate.

- 55% Poly UAN – For solutions that use standard quality polyphosphate and UAN solution as their primary ingredients.

- 70% Poly UAN – For solutions that use higher quality polyphosphate with UAN solution as their primary ingredients.

- No Poly Urea – For solutions that use Urea solutions and no ammonium polyphosphate solution.

- 55% Poly Urea – For solutions that use standard quality polyphosphate and Urea solution as their primary ingredients.

- Base Grade – This is a Product that can be pre-loaded. This inventory item must be listed in the Product Set and have the percentage filled out to preload. For this to show up on a Field Plan, there must be a % of Base to Preload figure other than zero. This Product is listed at the top of a Blend Ticket (just under water if water is also preloaded) regardless of its Blend Order status in the list of Products.

- Suspension Blend Target % – The total analysis % (sum of the nutrients’ percent concentration) that the guaranteed analysis cannot exceed when formulating a Suspension blend. If the percentage is higher than this number, a prompt appears for the blend operator to decide if water is to be added to the blend until the total of the nutrients’ guaranteed analysis is at or below this setting.

- P% Guaranteed Limit – This upper limit setting for the P2O5 Guaranteed Analysis adds water to the blend until this blend’s P2O5 guarantee is at the upper limit entered here. This is used by companies when the amount of a Product should be limited, such as Acid, to keep the fertilizer mixture from getting too hot. A setting of 999 deactivates this checking (999 = Off).

- % Chlorine Warning – The percentage at which a warning is displayed after formulating a blend. If set to zero, the warning is disabled (0 = Off).

- % Water to Preload – If completed, the percentage of water is listed first on the Blend Ticket regardless of its Blend Order.

- % of Base to Preload – If completed, the percentage of the Base Grade Product is listed first on the Blend Ticket regardless of its Blend Order.

Note: Checking this box allows the program to verify the salt out temperature during formulation and adjust if needed. This checkbox is only available for the Suspension Product Sets when Use Equations is not checked. One of the Salt Out Parameter Systems must be set to formulate to a salt out temperature. If formulating to a given salt out temp, then set the Suspension Blend Target % to 999.

Note: Checking this box allows the program to verify the salt out temperature during formulation and adjust if needed. This checkbox is only available for the Suspension Product Sets when Use Equations is not checked. One of the Salt Out Parameter Systems must be set to formulate to a salt out temperature. If formulating to a given salt out temp, then set the Suspension Blend Target % to 999.